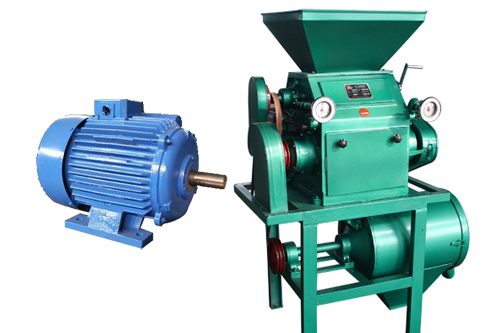

How to maintain the motor of flour machinery complete equipment?

The motor is the key part of flour machinery complete equipment processing. So it is necessary to keep the motors in good condition.How to keep motors in good condition?

1. Carefully inspect and maintain the various electrical components of the control motor to reduce the failure rate. The overcurrent short circuit protection device should be periodically checked to ensure reliable and sensitive operation.2. During the maintenance process, it is necessary to ensure that various parameters meet the standard requirements and strictly control the quality of the replaced parts and the enameled wire. Reasonable and correct operation of each process to prevent hidden dangers of various accidents and improve the quality of motor operation after repair.

3. In addition, it is necessary to continuously strengthen the comprehensive management of the operation of flour machinery complete sets of equipment. For example, in the process of using the motor, the liability system is strictly implemented. The maintenance personnel regularly check the number of inspections every time, observe and monitor the motor, and find out the problems in a timely and effective manner.

The operator should do regular inspection and maintenance of the flour machinery equipment. In particular, when performing annual major repairs, attention should be paid to the disassembly and maintenance of the motor, the replacement of the bearing cleaning and fueling, the insulation monitoring, the improvement of the cooling system, etc., to ensure normal operation.

When the flour machine completes the equipment, if it encounters excessive power consumption, it will not only increase our production cost, but also increase the loss of equipment. Therefore, we must do a good job in the maintenance of the complete set of flour machine equipment. So, how should we reduce the power consumption of the flour machine equipment?

Here is a brief introduction:

- Frequent maintenance of the flour machine equipment to avoid the increase of electricity due to the wear and tear of the parts.

- reduce impurities into the flour machine complete sets of equipment, because impurities are very likely to cause damage to the equipment, thereby increasing power consumption.

- the use of good quality flour machine complete sets of equipment can save power consumption, thereby saving production costs.

Why choose turnkey flour mill manufacturer KEMC?

- Most Turkey flour mill manufacturers get their flour mills from KMEC. These have gained a remarkable reputation over time for stocking and selling flour mills from KMEC for commercial production of different types of flours from wheat, maize, rice, sorghum and so forth. If you have not had a chance to learn about them, then it is almost certain that you have used one of their flour products, through purchase of flour products processed with their exemplary products.

- KMEC is the perfect that anyone after a satisfying flourmill will check out. Well, there are so many factors that the experienced buyer will need to put into consideration apart from prices, energy efficiency and so forth but rest assured, the products from these manufacturer are what you have wanted in a flour mill. The quality of their products have won the hearts of many users since they came to the industry a number of decades ago, oftentimes, resulting to referral sales.

- If you want to experience quality, then you want to check the KMEC group of flour mill manufacturers out. The quality of their products is the one thing that makes them unique and this is what any buyer wants to have, right? This ensures that the finished flour is of the highest possible, good for your business if you are in commercial production. The price of a flourmill is another factor that a user will have to consider. With these manufacturers, any user will find the ultimate machine for the intended application, without worrying about formidable costs. The cost of installation is also very reasonable.

- The flexibility of the products of the KMEC flour mill manufacturers is something that the user will find very comfortable. With so many flour-milling recipes to experiment with using a single flour- mill, the process is one time, whatever the type of flour intended.