What you should pay attention when operating maize milling equipment?

Grasping the operation steps of the correct maize milling equipment can not only increase production efficiency, but also increase the service life of the maize milling equipment and reduce the accidental injury to the operator during the operation. Therefore, the maize milling equipment needs to be operated. What problems we should pay attention? Let's take a look with the author.

Strictly abide by the working safety regulations for the maize milling equipment and flour production line, and wear the labor protection articles according to the operation regulations.

Rules you should follow

- Be sure the motor, switch, circuit and grounding line is normal before starting and check carefully. Check whether the maize mill equipment is firmly fixed on the ground or the floor, check all the operation parts and buttons, make sure they are in the correct position.

- Check the coincidence and sturdiness of the upper and lower molds, check whether each positioning device meets the requirements of the regular inspection of the upper and lower mold coincidence. Check the pressure gauge to see if the pressure is within the specified range.

- After the maize milling equipment started about 2 minutes, if abnormal sounds or faults are founded, it is necessary to stop the equipment immediately and solve the problem. After the equipment is in normal operation condition, it can start working again. Abnormal situation happens, shutdown the flour milling machine immediately, find the cause of the abnormality and eliminate it in time.

- When you re-pour maize in the mill, you must cut off the power supply and stop the equipment. When the maize milling equipment is working, the rear part of the flour mill plant is not allowed to for anyone to stay. If abnormal operation is found, it is necessary to stop and fix it. It is forbidden to use hands to fix the equipment during operation to avoid injury to hands or human being.

- If the body of the equipment shakes heavily, tight the bolts between the grinding head and the frame. When the output drops, the spring should be tightened to ensure that the gap between the two ends of the grinding roller is consistent and timely repairs are performed on the worn grinding gear.

- The temperature of the flour is high, it might be too tight of the roller, loosen the flour machine roller for some degree. if the roller wears seriously, it should be repaired or replaced. when the machine temperature is too high, it needs stop to cool for some time. When meeting the situation of no production of bran, it might be the wrong direction of spindle, sieve is not sealed tight or the screen is broken.

- If there is no output of flour or the flour production is obvious less, it is because the screen is blocked. The mechanical voltage is too low, the line of the distribution line is short, the line is in poor contact, the control circuit is disconnected, the fuse is blown will result in failure to start the maize flour equipment. When using the maize flour equipment, the parts of the machine must be lubricated from time to time to reduce their wear and tear.

Advantages of KEMC maize milling equipment

- Pneumatic roller and conveying system helps us to save labor and intensity.

- The maize milling equipment is small in size and have a compact structure which makes it easier to install and operate.

- The maize milling equipment is high efficient but energy saving.

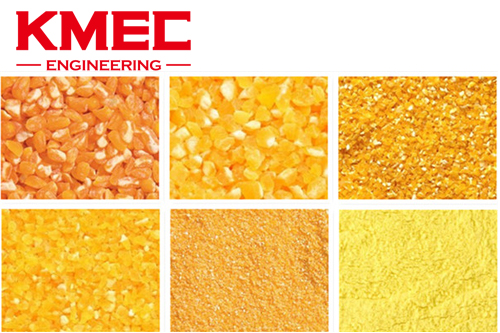

KMEC is a famous manufacturer of maize milling equipment and wheat milling equipment in China. We produce and supply maize milling equipment for markets worldwide. You can produce maize flour or maize grit by using our maize milling equipment. There are plenty of maize milling projects you can see in our projects.