where to find cassava flour milling plant?

Features of cassava

Running a cassava flour mill can earn you extra income, provide employment opportunities and serve as a reserve food in times of scarcity.

Cassava is a multifunctional plant that every part of the cassava plant is useful, the leaves of cassava can be used to make soup or animal feed, the stems can be used for planting more cassava, or as wood fire, they can also be used to grow mushrooms. The main part, root, can be processed into cassava flour or eaten fresh.

To day, we are going to discuss how to turn cassava into cassava flour. High quality cassava flour is made within a day using fresh cassava that harvest the day that being milled into flour. It is different from the traditional cassava flour that is white and fresh, with no sour smell and low fat content. They can be used fixing with wheat flour to make bread or cakes.

What you need to make high-quality cassava flour?

To establish a small-scale cassava flour mill plant to make high-quality cassava flour, you require:

• enough space for cassava processing, cassava milling machine and other cassava processing equipment.

• plenty cassava roots to make flour

• cassava processing equipment (knife, bowl, drying platform, grater, press and cassava milling machine)

• gtrained machine operators along with casual workers for peeling, washing, grating, pressing,drying, milling, sifting and packing.

How to make high-quality cassava flour?

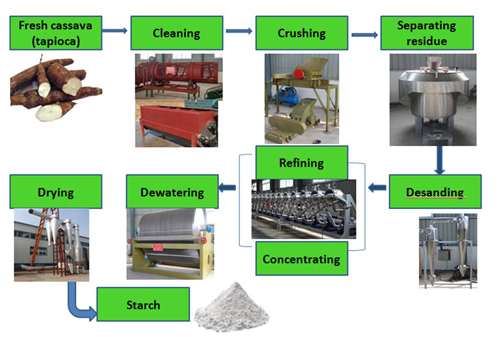

The production process of cassava flour mill plant includes: raw material washing, peeling, rough crushing, fine crushing, residue and starch slurry separation, starch slurry refining, dewatering, airflow drying, dressing and packaging.

Step 1: Choosing fresh cassava roots

While selecting cassava root, you can buy or harvest, if it is promise, healthy, mature, firm and fresh cassava roots without bruises or perish. The flesh of the cassava roots should be white with no cracking and few fibrous roots.

Step 2: Peeling

Peel the cassava root and remove the stalk, woody tips and any fibrous root by using a sharp knife or a useful rasper. The unpeeled cassava roots after process will result in off-colour in the final product. Dried cassava peel can be used for animal feed or composting - so do not waste it!

Step 3: Washing

After peeling. Cassava roots that maintain it’s flesh need to be washed by clean water to remove mud, sand or other impurities.

Step 4: Grating

Use a mechanical grater or decorticator to grate cassava roots into a fine mash.

Step 5: Pressing

Pack the grated cassava mash into a clean bag, such as a jute or sisal sack that will allow extrawater to escape. Press the sack using a screw press or hydraulic jack to remove excess water until the cassava is crumbly.

Step 6: Drying

Spread the pressed cassava mash thinly on a clean black plastic sheet placed on a gentle slope in full sun. Ideally this should be raised off the floor. Dry mash until it is very floury. Cover with netting to keep off flies and birds.Though solar, stove and hot-air dryers are more expensive, the drying process is more reliable and of higher quality.

Step 7: Milling

Using cassava mill to mill the dried cassava mash to produce flour. Milling can be done using a hammer crusher or a cassava mill.

Step 8: Sifting

Using a high efficient cooling starch sifter, sift the milled flour to remove fibrous materials and any lumps. This is important to obtain high-quality free-flowing flour, free of fibre with a good particle size.

Step 9: Packaging and storing

Pack sifted cassava flour using auto packing machine. Do not forget the label with date of manufacture and expiry date. Pack bags in a carton to protect them from light. Store the cartons in a well-ventilated, cool, dry place. The packaged flour will keep for about six Months.

If you are interested in our cassava milling plant, do not hesitate to contact us, send us e-mail or chat on line, we will be glad to help you.