The characteristics of vibrating sieve of maize grits processing plant

The characteristics of vibrating sieve of maize grits processing plant

The maize grits processing plant is composed by series connecting parts, and today we will take the vibrating sieve as an example to talk about maize flour supporting equipment. We will discuss the vibrating sieve by it’s classification and characteristic.

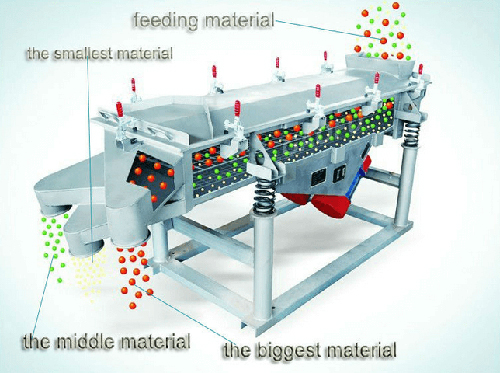

According to the different working track, vibrating sieve can be divided into two types, one is round-cycled vibrating sieve while the other one is “straight” type vibrating sieve.

The round-cycled vibrating screen includes inertial vibrating screen, self-centering vibrating screen and heavy vibrating screen. The linear motion vibrating screen includes linear vibrating screen and resonant screen.

The vibrating sieve is the most popular and common seen sieve in the maize grit processing plant and wheat flour production machine. The following aspects are reasons why vibrating maintain the head of sieves.

- First of all, the sieve body is strongly vibrated with low amplitude and high vibration times, accelerating the delamination of the material on the sieve surface and the speed of passing through the sieve hole, so that the sieve has high productivity and screening efficiency.

- Secondly, due to the strong vibration of the screen surface, the sieve holes are less blocked. When sifting the sticky or wet materials, the working index of the corn processing equipment is obviously superior to other types of sieves. Then, the required screen area is smaller than other sieves, which can save the area and height of the plant, and the power consumption is small, and the operation and maintenance are convenient.

- Finally, it has a wide range of applications, both for pre-screening and screening before medium and fine crushing.

There are three types of screen that KEMC can provide you

vibrating screen, rotary screen and cylindrical screen

The TQLZ series high quality vibrating screen is the main product, it utilizes double vibrationmotor to drive the altermating motion of the screen, and the screen can clean both big and small impurities in the wheat or maize. The vibrating screen is maily used in wheat flour making, maize flour milling and aslo other flour milling fields.

Rotary screen, TQLM series rotary screen depends screen circular motion to get ride of the impurities in grain. This series of rotary screen also adopts vertical suction pipe or circulation air separator to get ride of the dust and impurities in grains. Moreover, if the screen equips with different sieves, it can be used to get ride of impurities in wheat, maize, rice and so on.

Cylinder screen, The cylinder screen is installed in grain receiving section of flour mill plant. Its inner cylindrical screen serves to separate coarse impurities from cereals during the pre-cleaning phase, such as straw particle, string, paper, pieces of wood, maize stalk and cobs, etc. While the outer cylindrical screen can get rid of the small impurities in grains; the dedusting part can remove dust and light impurities.

Why choose KEMC as your auto flour mill manufacturer?

Henan KEMC Flour Machinery Co., Ltd. is a comprehensive company integrating flour mill design, production, manufacture and sales. The main products include all kinds of flour complete sets of equipment, corn mill complete sets of equipment, wheat mill complete sets of equipment, flour stand-alone equipment, etc. Milling machine, high square sieve, powder cleaning machine, supplemented by impact pine powder process, forming a new milling process of grading and sieving outside the screen, and light grinding and fine grinding of long powder road, which can be used to produce special flour powder, fine flour powder.