10-100T Corn Flour Production Line

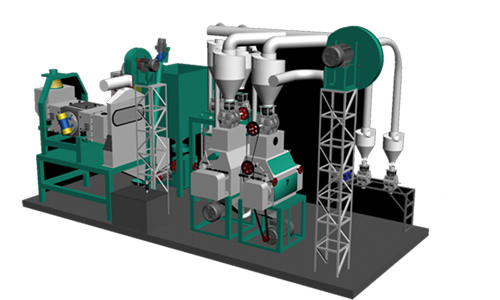

10-20T corn flour production line

10t/d small corn flour production line

The 10-100t/d small corn flour production line is used in making corn grits and corn flour. There are cleaning machine, peeling machine, degerming machine, corn flour milling machinery or corn grit mill. The highlight of this mini corn plant is that adopts high technology peeling and degerming technology to extract pure endosperm. Corns through the corn milling machinery and the grading of bolting equipment can produce high quality corn grits and corn flour.

structure of 10t corn flour production line

Features of 10-20T corn flour production line

- Pneumatic conveying system helps to save labor and intensity.

- Compact structure and small size make it easy to install and operate,

- Low power consumption but high efficiency.

Small corn flour production line include: 10TPD, 15TPD, 20TPD

10t/d corn flour production line

10t/d corn flour production line  15t/d corn flour production line

15t/d corn flour production line 20t/d corn flour production line

20t/d corn flour production line30-100T/D middle corn flour production line

The 30-100T/D corn flour production line is lager than the small corn flour production line in size and contains more corn milling machinery. This line also includes cleaning machinery, peeling & degerming machinery, and corn milling machinery or corn grits machinery. The steel structure can save covering area and looks good.

30t/d corn flour production line

30t/d corn flour production line 50t/d corn flour production line

50t/d corn flour production line 100d/corn flour production line

100d/corn flour production lineFeatures of 30-100T/D corn flour production line

- Steel structure not only takes less space but also have longer service life.

- Advanced peeling and degerming technology can not only extract pure endosperm but also making corn germ oil.

- Easy to operate and saves man power, high output rate.

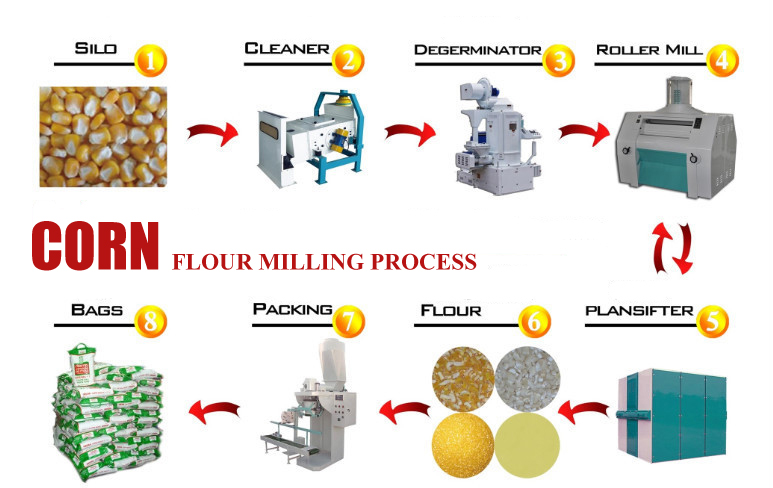

Technological process of milling corn flour

Under the power of high pressure fan, corn is conveyed into the combined sieving and destoner, where both big and small impurities and stones are eliminated. Then corn is fed into the peeling machine for removing clod, dust or other impurities. After that, the corn enters crusher and is grinded into big particles to prepare for making flour.

After crushing, corn particles are elevated and fed into the stock bin of corn flour milling machinery. Then they are blown into the corn milling machinery. After grinding, corn flour is sifted: those under the sieve will be packed, while those above the sieve will go back to the stock bin for second time grinding.